Technology

Innovation in microparticle detection

MLEIS - experience real-time analysis

through Deep learning and impedance

spectroscopy.

MLEIS - experience real-time analysis

through Deep learning and impedance spectroscopy.

spectroscopy.

MLEIS – The underlying technology

Machine Learning Enhanced Impedance Spectroscopy (MLEIS) combines precise impedance measurement with artificial intelligence. Unlike optical or laboratory-based methods, MLEIS detects particles directly in the flow and automatically evaluates signals in real time. This allows microplastics, biological particles, and air bubbles to be reliably distinguished—efficiently, scalably, and independently of optical influences.

Impedance spectroscopy – The principle of precise particle detection

Impedance spectroscopy – The principle of precise particle detection

Impedance spectroscopy is based on measuring the dielectric properties of particles using electromagnetic waves that pass through the sensor. This method captures precise information about the size, composition, and quantity of the particles. This enables detailed analysis of microparticles and air bubbles in various liquid media.

Deep Learning - Algorithms for precise analysis

Our AI algorithms analyze complex impedance signals and recognize characteristic patterns in real time. Through continuous training with validated data sets, the system learns to distinguish particles precisely by size, material, and concentration. This results in a highly accurate, adaptive analysis that continuously improves and delivers reliable results.

Real-time - data for immediate decisions

Real-time - data for immediate decisions

Our sensor system operates on the flow-through principle and provides continuous real-time data, which can be processed immediately, made available on an internal platform, and used for instant analysis. This gives companies, facilities, and research institutions continuous, accurate insights into microplastic levels, enabling real-time process optimization and data-driven decision-making.

Request product data sheet.

Would you like to receive detailed technical information about our ZAITRUS sensor system? We will be happy to send you the current, complete product data sheet by email.

Technical specifications

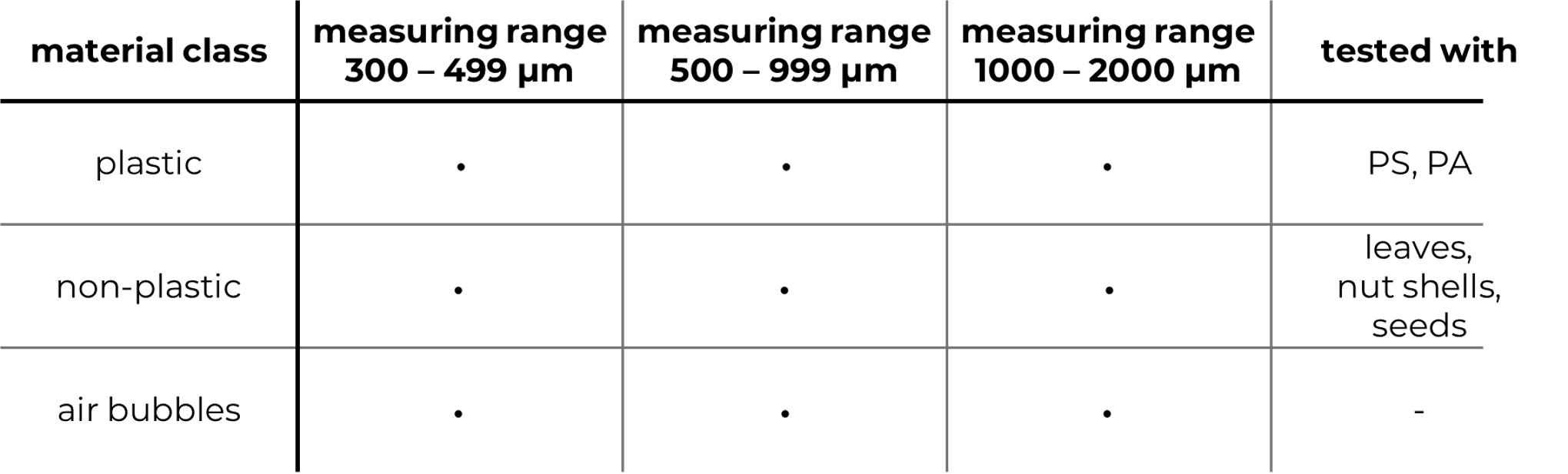

Measured components and measuring ranges

Solid particles in the ranges 300-499 µm, 500-999 µm, and 1000-2000 µm are typically detected.

In addition, the following materials are divided into the following classes.

Tested media fluids: Tap water and fresh water

Tested conductivity levels: 300, 500, and 1000 µS/cm respectively (full conductivity range to follow shortly)

Connection types and specifications

- Size 6/8 mm silicone tubing

- Pressure: max. 1 bar

- Flow rate Approx. 500 ml/min

Performance

- 99% detection accuracy in the above-mentioned size ranges

- 90% classification accuracy in the above classes

Conditions

- Ambient temperature +15 to +25 °C (in operation)

- Relative humidity ≤ 75%, max. 95% for short periods

- Max. particle concentration 5000 particles/liter (in the range 1000-2000μm)

Our innovation

Real-time microplastic monitoring

With ZAITRUS, microplastics become visible directly in the flow and in real time for the first time. Our sensor system detects and classifies particles according to size and material without the need to take samples or send them to a laboratory. Instead of selective spot checks, you receive complete real-time data that makes processes transparent and enables immediate decision-making.

Real-time data acquisition and transmission

- Flow-through monitoring without sampling

- Complete data series instead of random sample

- Data collection without laboratory tests

Classification by size and material

- Identification of particles

- Quantification of particle pollution

Detection

in case of contamination

Less effort per measuring point

Get in touch with us.

Whether you have questions about technology or are interested in our solutions, we are here for you. Contact us to learn more or discuss your concerns with us.

We’re excited to hear from you.

Get in touch with us.

Whether you have questions about technology or are interested in our solutions, we are here for you.

Contact us to learn more or discuss your concerns with us.

We’re excited to hear from you.